Geotextile for embankment and ground reinforcemente

ADEAM (HG type)

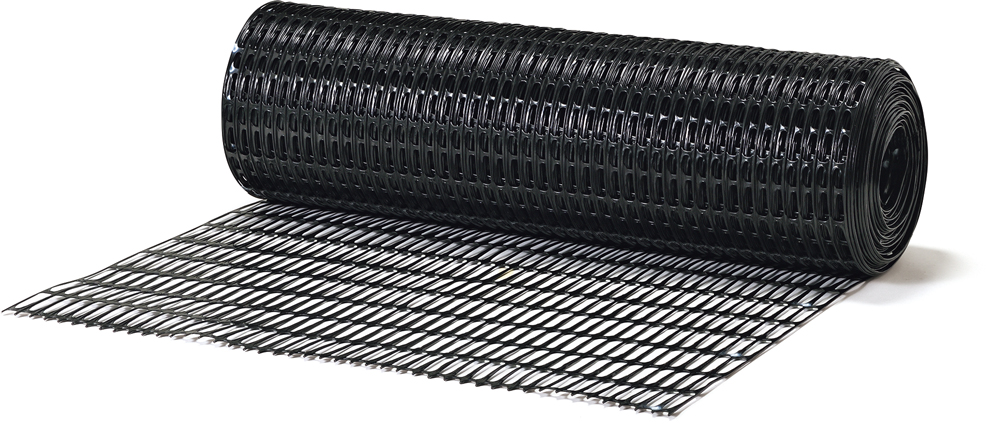

- Geogrid products

- Obtained Construction technology examination certificate: No. 0804

New Technology Information System (NETIS) Registration Number:KK-980079-VE (End of publication period) 2017 Utilization Promotion Technology (New Technology Utilization Evaluation Conference)

New Technology Information System (NETIS) Registration Number:KK-980079-VE (End of publication period) 2017 Utilization Promotion Technology (New Technology Utilization Evaluation Conference)

Outline

The definite geotextile for embankment and ground reinforcement in various applications

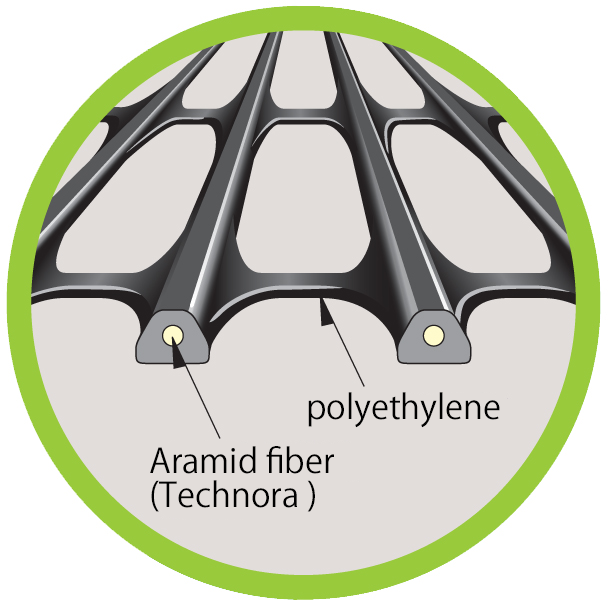

ADEAM is a high-strength, low-elongation, low-creep strain geotextile made from aramid fiber (Technora®), strongly confines the soil and exerts its strength in embankment and ground reinforcement.

There are two types: “HG type” in which aramid fibers are inserted into a polyethylene net, and “F type” in which a grid-style woven fabric in which polyester fibers and aramid fibers are interwoven.

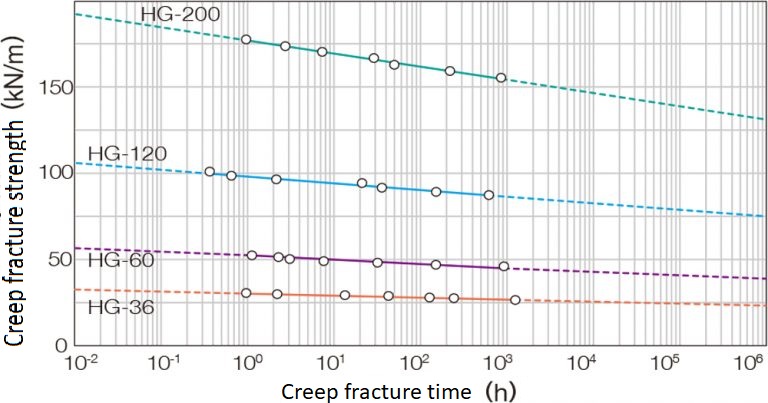

The HG type has a wide range of limit tensile strength of 22 to 120 kN / m considering creep, and the appropriate product can be selected according to the applied site.

Supplementary material

Characteristics

- High strength and low elongation characteristics enable to confine the soil, and build a stable embankment with less deformation.

- Excellent friction with soil

- Excellent weather resistance, chemical resistance, cold / heat resistance and impact resistance

- Possible to select the product with the optimum limit tensile strength, which brings the reduction of construction costs.

- Enables to build a vertical wall (reinforcement of the back embankment of the vertical retaining wall) by ADEAM Wall

- Enables to build a green steep embankment by the ADEAM Unit Cap Construction Method

Application

Reinforcement of the back embankment of the vertical retaining wall

Reinforcement of greening steep embankment

Reinforcement of high embankment on gentle slopes

Standard / specification

HG Type

| Product No. | Mesh (mm) |

Width (m) |

Length (m) |

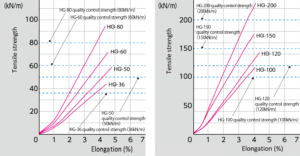

Quality control strength (kN/m)※1 |

Elongation (%) |

Product standard strength (kN/m)※2 |

The Limit tensile strength (kN / m) considering creep |

|---|---|---|---|---|---|---|---|

| HG-36 | 100×28 | 1.2 | 30 | 36 | 4.5 | 34 | 22 |

| HG-50 | 100×28 | 1.2 | 30 | 50 | 4.5 | 47 | 30 |

| HG-60 | 100×28 | 1.2 | 30 | 60 | 4.5 | 57 | 37 |

| HG-80 | 100×28 | 1.2 | 30 | 80 | 4.5 | 76 | 49 |

| HG-100 | 50×28 | 1.2 | 30 | 100 | 4.5 | 93 | 60 |

| HG-120 | 50×28 | 1.2 | 30 | 120 | 4.5 | 112 | 72 |

| HG-150 | 50×28 | 1.2 | 30 | 150 | 4.5 | 139 | 90 |

| HG-200 | 50×28 | 1.2 | 30 | 200 | 4.5 | 185 | 120 |

- * The mesh indicates “warp x weft”.

- * Quality control strength and growth rate both indicate “warp”

- * 1 Quality control strength: Standard strength in quality control tests (width of speciment [1 strand] / tensile strain speed [50% / min]) to check quality during product manufacturing under standard test environment.

- * 2 Product standard strength: The base strength for designing reinforced soil with ADEAM, and is the standard strength in performance confirmation tests (test specimen width [wide- width 22.4 cm] / tensile strain speed [1% / min].

Characteristics

Tensile strength

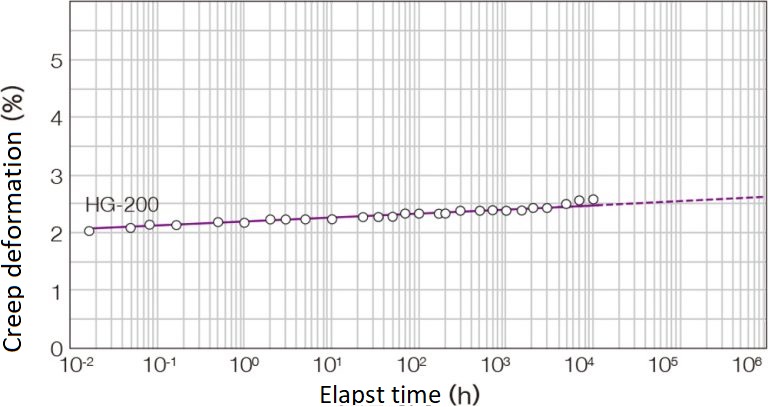

Creep properties

Related products / construction methods

disaster recovery / maintenace road / mountain / slope / Solar power generation / wind power generation