Multifunctional special polymer cement mortar

MAGNE LINE

Outline

Inorganic materials with various functions for

reinforcement, repair, and rust prevention

MAGNE LINE is a multifunctional special polymer cement mortar that uses an inorganic main ingredient MAGNE compound and a composite polymer emulsion MAGNE Emulsion.

It has various functions for reinforcement, repair, and rust prevention.

Characteristics

- Easy handling and reliable reinforcement

- It has passed the water supply equipment leaching test

- Excellent aesthetic after reinforcement

- It works well with iron and concrete

- Available in wet condition

- The performance is shown in the manual issued by the PCM Method Association, and it can be checked such as neutralization and salt damage.

The manual issued by the PCM Method Association

Application

Salt damage countermeasure

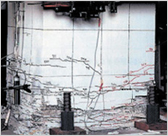

Positive and negative alternating load test

RC floor slab bottom surface thickening

Seismic reinforcement of parking lot pillars

Repair of open channels

Installing reinforcing bar

Anti-corrosion coating for steel sheet jacketing

Concrete repair method

Standard / specification

Characteristics of MAGNE LINE

| Type I | Type II |

|---|---|

| Reinforcement method : spraying, brushing, roller coating Main application : Used as adhesive and primer material |

Reinforcement method : Iron coating, spraying (thickening) Main application : Used as thickener |

|

|

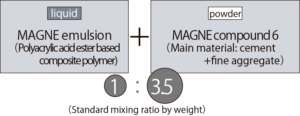

MAGNE LINE type I

| Item | Standard value | Test value | Test method |

|---|---|---|---|

| Emulsion: Compound (weight ratio) | - | 1:3.5 | - |

| Unit volume weight (ton/m3) | - | 1.8 | - |

| Adhesive strength (N/mm2) | 1.5 | For iron plate 2.1, for Concrete 3.1 | JIS A 1171:2000 compatibl |

| Freezing and thawing test (%) | - | Relative dynamic modulus of elasticity 97 | JIS A 1171:2000 |

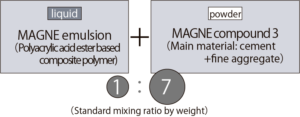

MAGNE LINE type II

| Item | Standard value | Test value | Test method | ||

|---|---|---|---|---|---|

| Emulsion: Compound (weight ratio) | 6.5 to 7.5 | 1:6.5 | 1:7.0 | 1:7.5 | - |

| Unit volume mass(ton/m3) | - | 2.0 | 2.0 | 2.0 | - |

| Compressive strength(N/mm2) | 30.0 | 41.2 | 44.8 | 54.5 | JIS A 1171:2016 |

| Bending strength(N/mm2) | 6.0 | 13.0 | 12.2 | 14.7 | JIS A 1171:2016 |

| Tensile strength(N/mm2) | - | 4.0 | 4.2 | 4.4 | JIS A 1113:2006 |

| Young’s modulus (kN/mm2) | 19.0 | 18.9 | 19.3 | 22.5 | JIS A 1149:2001 |

| Bond strength with concrete*1(N/mm2) | 1.5 | 2.0 | 3.0 | 2.8 | Adhesion test of BUILDING RESEARCH INSTITUTE method |

| Neutralization rate coefficient*2(mm/√year) | - | - | 0.17 | - | JIS A 1171:2016 |

| Chloride ion diffusion coefficient(cm2/year) | - | - | 0.38 | - | JSCE-G 572-2007 |

| Curing shrinkage(%) | - | - | 0.049 | - | JIS A 1129-3*3 |

| Linear expansion coefficient(10-6/℃) | - | - | 15 | - | JIS K 6911 |

- *The standard value composition is Emulsion: MAGNE compound No. 3 =1:7

- *Other test conditions are in accordance with each test method.

- *1 : Standard values are SPCM quality standards, which are different from characteristic values.

- *2 : Converted to a carbon dioxide concentration of 0.03%

- *3 : Conforms to the conditions of NEXCO Structure Management Guidelines 2016 “Performance check items for cross sectional restoration by plastering method”