FRP net material for peeling prevention

HARD MESH

New Technology Information System (NETIS) Registration Number:KT-190006-A

New Technology Information System (NETIS) Registration Number:KT-190006-A

Outline

Thin and high rigid net fits on the frame surface and can prevent concrete peeling.

HARD MESH is a grid material integrated FRP structure and glass mesh for preventing small concrete piece peeling in a tunnel. By fixing it to the surface of the tunnel lining, small concrete pieces are prevented from peeling off.

Characteristics

- It has outstanding stiffness even thin because FRP structure is made of carbon fiber grid.

- Integrated glass mesh prevents small concrete piece peeling.

- Since specialized washer and expansion anchor are used for fixing HARD MESH, it is possible to check the frame near the anchor after installation.

HM Specialized washer

Fixing method

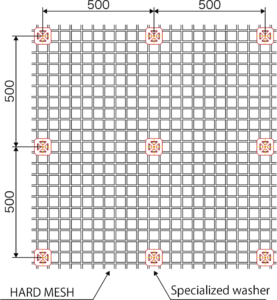

- Make sure to use specialized washers and expansion anchors to fix HARD MESH.

- The standard fixed pitch of HARD MESH is 500mm.

- Install the joints by overlapping one square.

【Precautions】

- Be sure to strictly observe the hole diameter of the expansion anchor. It affects anchor strength. Note the case of shallow hole is the same.

- Tighten the nut with the recommended torque value.

- Wear gloves in handling because the end of the grid and special washer are sharp.

Standard / specification

Standard

HARD MESH

| Product No | Cross-section area (mm2) |

Tensile strength (N/mm2) |

Tensile elasticity (kN/mm2) |

Tensile stress (kN/anchor) |

Tensile stiffness (kN/anchor) |

Pitch (mm) |

|---|---|---|---|---|---|---|

| HM-C11 | 11.1 | 1,200 | 95 | 13.3 | 1,054 | 50×50 |

Expansion anchor

| Product No | Dimensions (mm) |

Material | Hole diameter | Hole depth | Recommended torque value | Remarks |

|---|---|---|---|---|---|---|

| MS-670LN | M6×70 (overall length) |

SUS304 | 6.4mm | 65mm or more |

8 to 10N*m | With lock nut |

HM dedicated washer

| Part number | dimensions (mm) |

Material | Remarks |

|---|---|---|---|

| HM-W75*1.5 | 75×75×1.5t | SUS304 | with opening |

- * For expansion anchors, consult us if the length have to be changed due to the depth of hole.

- * Packing … Expansion anchor: 100 pcs. / box, HM washer : 100 pcs. / box

Performance

| Measures against peeling Performance | Fire spread and selfextinguishing properties | Generated gas safety | |||||

|---|---|---|---|---|---|---|---|

| Pull-out performance (Net-type / Saddle-type Construction Method) | Result | Fire spread range | Specimen left-right direction | 230mm | Mouse action stop time: 14.6minutes |

||

| Load displacement | At load 0.5 kN | 44.6mm | Top direction of specimen | 185mm | |||

| Fire spread time | Burning time | 10minutes | |||||

| Fire spread time | 0second | ||||||

- *According to the NEXCO test method (Pullout performance test method 737-2011, Fire spreadability / Self-extinguishing test 738-2011).

- *A test method that confirms that “no fumes or gases harmful to evacuation are generated” in the Building Standard Law for the safety of generated gas.