Drilling type post-installed adhesive anchor

BOLTMATE TG

JCAA (JAPAN CONSTRUCTION ANCHOR ASSOCIATION) certified product(Excluding some part number)

Outline

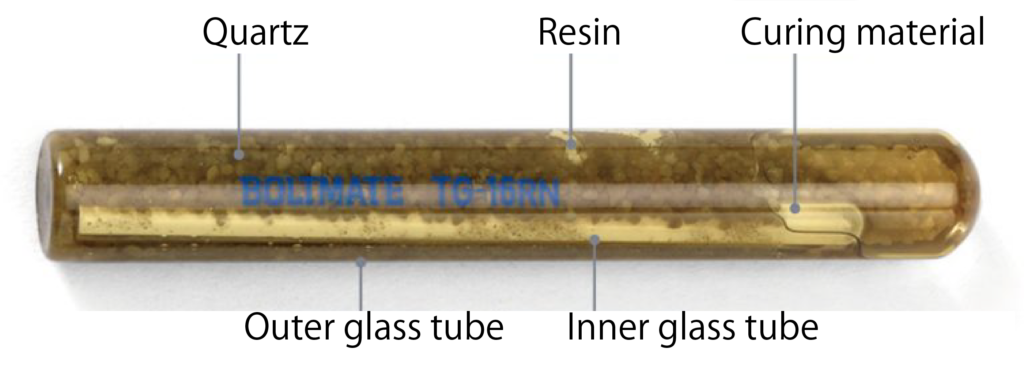

Adopted double glass capsule

Drilling type adhesive anchor

Boltmate TG is a double-capsule type chemical post-installed adhesive anchor that contains styrene-free epoxy acrylate resin and aggregate, and a curing agent in separate glass tubes. By adopting styrene-free resin that does not contain “VOC (volatile organic compound) 13 substances” and “styrene and 9 other substances”, it has become a product that can be used safer than ever before.

Characteristics

- Adopting styrene-free resin makes less unpleasant odor during construction, and makes the product environmentally and human-friendly.

- By adopting high-performance epoxy acrylate resin, strong adhesion and excellent alkali resistance are obtained.

- It can be installed the construction both sideways and upwards.

- Excellent storage stability due to the adoption of double glass capsule

- JCAA product certified product (For the details of the product certification, contact to sales representative.)

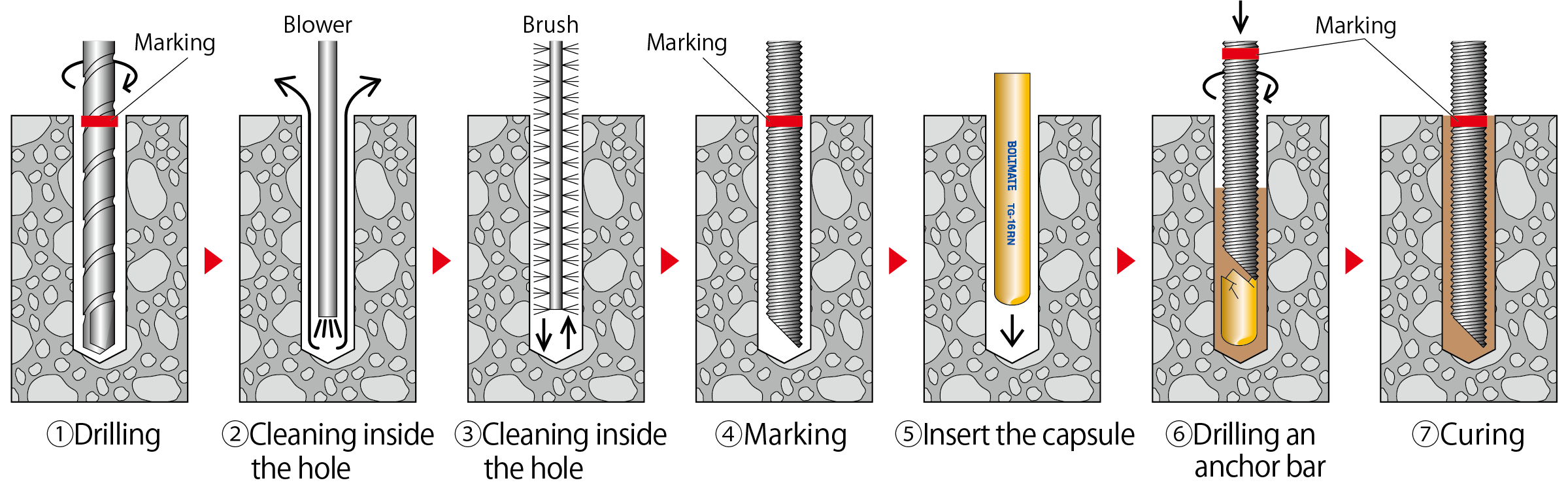

Installation procedure

*!Caution!* ①Check the drilling diameter and drilling length, mark the drill pit, and then install. ② , ③ Blower (vacuum cleaner) → Brush → Blower removes chips in the hole in this order. ④ Mark the anchor bar according to the actual drilling depth. ⑤ Insert the capsule with the rounded tip facing the bottom of the hole. * If the orientation is reversed, the resin may easily drip during sideways or upward construction. ⑥ Make sure to embed the anchor bar to the bottom of the hole while drilling. However, excessive stirring is strictly prohibited. * Leaked resin may become powdery, but there is no problem with quality. ⑦ After embedding, do not move the anchor bar within the specified curing time.

Installation movie

Application

- Seismic reinforced wall

- Installation of equipment

- Installation of road accessories such as noise barriers and guardrails

- Sign / signboard installation, cable / pipe support

Standard / specification

Standard / specification

| Standard type | Anchor bar | Reference drilling conditions | Maximum tensile load (kN) ※Fc=21N/mm2 |

Allowable tensile load (kN) ※Fc=21N/mm2 |

|||||

|---|---|---|---|---|---|---|---|---|---|

| Product No. | Outer diameter x length (mm) |

Amount (ml) |

Diameter( (mm) |

Depth (mm) |

Long term | Short term | |||

| TG-10RN | 10.8×90 | 6.5 | M10,W3/8 | 12 | 90 | 61.0 | 12.4* | 18.6* | |

| D10 | 13 | ||||||||

| TG-12RN | 12.7×100 | 10 | M12,W1/2 | 14.5 | 100 | 83.1 | 15.1* | 22.7* | |

| D13 | 16 | ||||||||

| TG-16RN | 16.8×120 | 21 | M16,W5/8 | 19 | 130 | 138 | 25.5* | 38.3* | |

| D16 | 20 | ||||||||

| TG-20RN | 21.5×175 | 51 | M20,D19 | 24 | 200 | 231 | 58.2* | 87.4* | |

| W3/4 | 23 | ||||||||

| TG-22RN | 23.8×200 | 69 | M22,W7/8 | 26 | 250 | 295 | 75.4* | 113.1* | |

| D22 | 28 | ||||||||

| TG-24RN | 27.0×255 | 125 | M24,W1 | 30 | 300 | 353 | 96.8* | 145.2* | |

| M27,D25 | 32 | 400 | 95.8* | 143.8* | |||||

| TG-30RN | 35.0×350 | 275 | M30,W11/4,D29 | 40 | 350 | 490 | 121.7* | 182.5* | |

| D32 | 42 | ||||||||

| Short type | Anchor bar | Reference drilling conditions | Maximum tensile load (kN) ※Fc=21N/mm2 |

Allowable tensile load (kN) ※Fc=21N/mm2 |

|||||

|---|---|---|---|---|---|---|---|---|---|

| Product No. | Outer diameter x length (mm) |

Amount(ml) | Diameter (mm) |

Depth (mm) |

Long term | Short term | |||

| TG-20SN | 21.5×130 | 33 | M20 | 24 | 130 | 126 | 24.8* | 37.2* | |

| TG-20EN | 21.5×155 | 43 | M20,D19 | 24 | 160 | 164 | 38.6* | 58.0* | |

| W3/4 | 23 | ||||||||

| TG-22EN | 23.8×165 | 53 | M22,W7/8 | 26 | 180 | 215 | 48.9* | 73.4* | |

| D22 | 28 | ||||||||

| TG-24EN | 27.0×185 | 85 | M24,W1 | 30 | 200 | 291 | 57.9* | 86.8* | |

| D25 | 32 | ||||||||

| TG-30EN | 33.3×240 | 160 | M27 | 35 | 250 | 400 | 75.1* | 112.6* | |

| M30,W11/4,D29 | 38 | 240 | 430 | 70.6* | 106* | ||||

| D32 | 40 | ||||||||

| Long type | Anchor bar | Reference drilling conditions | Maximum tensile load (kN) ※Fc=21N/mm2 |

Allowable tensile load (kN) ※Fc=21N/mm2 |

|||||

|---|---|---|---|---|---|---|---|---|---|

| Product No. | Outer diameter x length (mm) |

Amount (ml) |

Diameter (mm) |

Depth (mm) |

Long term | Short term | |||

| TG-12LN | 12.7×145 | 15 | M12 | 14.5 | 145 | 86.1 | 33.0* | 49.5* | |

| D13 | 16 | ||||||||

| TG-16LN | 16.8×160 | 29 | M16 | 19 | 180 | 163 | 50.5* | 75.8* | |

| D16 | 20 | ||||||||

| TG-20LN | 21.5×210 | 61 | M20 | 24 | 250 (245) |

237 | 75.8* (73.8*) |

113.7* (110.8*) |

|

| D19 | 24 | ||||||||

| TG-22LN | 23.8×240 | 84 | M22 | 26 | 290 | 288 | 92.2* | 138.4* | |

| D22 | 28 | ||||||||

- * Allowable tensile load is a calculated value determined by concrete fracture when using high-strength metric thread under standard drilling conditions. Compare with the allowable load of the anchor bar, and set the weaker one as the allowable load.

- * The maximum tensile load is a test value obtained by a public institution when using using high-strength metric thread under the standard drilling conditions, and is not a standard value. (By JCAA Post-installed adhesive anchors test method) In addition, TG-24RN (M27), TG-30RN, and TG-30EN are in our test sites using the close contact method. The each fracture mode during the long type test is anchor bar fracture.

- * The maximum tensile load of TG-20LN is the test value when the drilling depth is 245 mm.

- * Standard (TG-10, 12, 16, 20, 22RN), short (TG-20SN, 20EN, 22EN), and long (TG-12, 16, 20, 22LN) can be drilled.

- Note: Although it can be installed underwater, the drilling diameter shall be smaller than that in the air to prevent from squeezing water and outflowing resin. The drilling diameter in water is shown below. Since there are other precautions, make sure to read the BOLTMATE Technical Data before using.

Curing time

The curing time of BOLTMATE HC depends on the temperature. Refer to the table below when using. Also, estimate about 2 times curing time in water. Since there are other precautions for installation underwater, make sure to read the BOLTMATE Technical Data before using.

| Temperature(°C) | -10 | -5 | 0 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Curing time(minutes) | 690 | 360 | 130 | 75 | 45 | 30 | 22 | 20 | 16 | 13 | 10 |